Prototyping

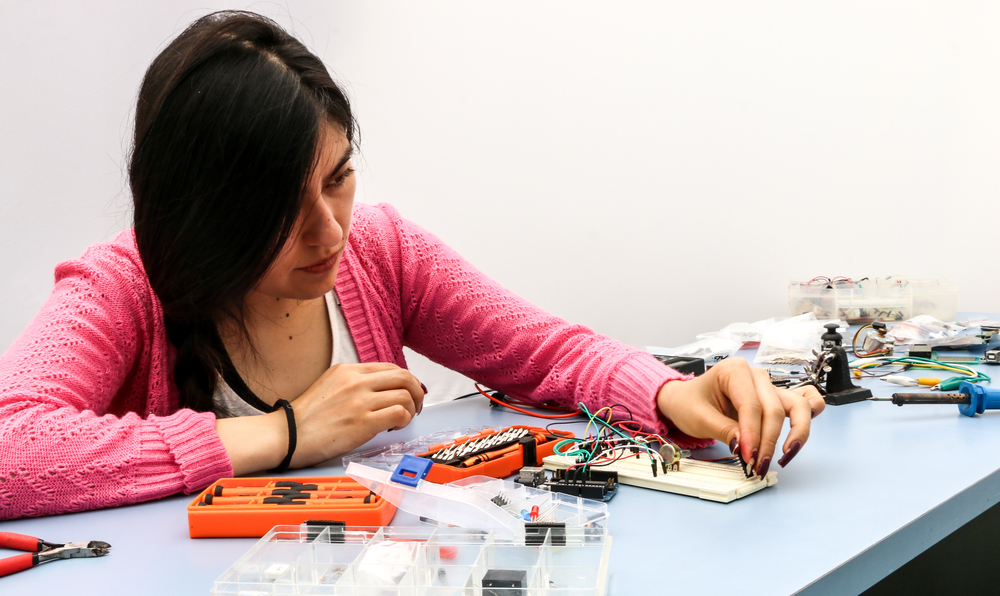

Beyond brainstorming, some may argue that there is no step more important in the invention process than creating a prototype. Being able to hold your idea and see it in action outside of your head…that alone is a powerful, one-of-a-kind feeling. Having a prototype used to be a luxury, especially if your idea was complex. The very concept of the current “rapid prototype model” was once the stuff of science fiction. Yet over the past few years, the boom in prototype production has helped hundreds, if not thousands, of amazing inventions find their core audiences.

Once, prototypes had to be created by hand from the material of choice. It was time-consuming and required specialized skills. Didn’t own a sewing machine? You’d better find somebody who does, or your prototype won’t be using fabric. Metal and wood required safety equipment and usually a workshop. Plastics were even more of a nightmare. In the 1980s, cutters could only move left and right or forward or back. Creating curves would mean using dremels, files, and knives.

Then came the 1990s, and with it, CNC technology. Using CAD to program the machines, circles could now be cut with ease. The pantographs previously used for cutting curves into flat plastic were gathering dust. By the 21st century, computers allowed inventors to draw their creations in 3D and work on all three axes. 3D printing in the mid-to-late 2010s revolutionized prototyping even further. Terry Wohlers, President of Wohlers Associates, said in an interview:

“Additive manufacturing (3D printing) technologies create a world of possibilities that can take an organization in an entirely new direction and help launch new businesses and business models. 3D printing and 3D imaging are causing design and manufacturing professionals to rethink their approach to new product development… As new additive manufacturing systems and materials become more widely adopted, I expect to see new designs that previously would have been very difficult or too expensive to manufacture.”

Keep in mind, Wohlers first said this back in 2012. It’s only rung more and more true in the years since.

Each decade, advancements in technology have made using plastics for prototypes even more accessible. For other materials, there were also revolutions. When it came to fabrics–both the usage and creation of–the Advanced Functional Fabrics of America (AFFOA) built their state-of-the-art headquarters in 2017. Companies like RevPart offer services to create rubber or plastic parts for prototypes affordably and efficiently. In the past few years alone, 3D printers have become common household appliances, making prototyping possible without the aid of a specialized company. Of course, these companies can produce better results, with far more materials, but inventors are less reliant on them.

More specifically, the past five years have created nearly exponential growth in the prototyping industry. In 2017, IBIS World reported a 16.5% growth in the 3D printing and rapid prototyping industry, reaching a revenue of $131 million. (Growth for 2018 had not been recorded at the time of this writing.) Within the same time period, the number of businesses in those industries increased by 11.5% and the number of employees went up by 14.3%.

This is all thanks to the rapid prototype model. Even the limited tools of the 1980s were the first steps to the process we know today. But RPM is more than simply visualizing your invention in 3D. It’s being able to check the efficiency and effectiveness of a product before mass manufacturing. You can test each individual element for durability, energy consumption, and output. Because the process is more accessible, making multiple prototypes to test small design tweaks is less risky and less expensive. This is only accented further by the rise of digital prototyping, or creating a virtual model of what the finished product will look like. Instead of having a physical copy of your invention, you have a virtual 3D model to show investors. This method is far less costly than a traditional prototype, but doesn’t suit all projects. For simpler ideas, a physical prototype might be the better option.

Indeed, having a prototype can cost you less in the long run. Being able to test your product and check for defects before mass-production can prevent modifications or even recalls in the future. It also aids in further streamlining the process, as viewing the production in real-time can help determine what steps can be altered or removed. Maybe two parts that were originally produced separately could be adjusted into one larger, more durable piece. This is something prototyping would help you discover before hitting the production line.

Another perk of having a rough prototype on hand is that it helps with your pitch. When first showing off your product to investors, even a very basic prototype can help garner interest. It showcases not only what the device is capable of, but also your own initiative and confidence in your product. However, most industry experts agree that having a basic prototype with customer interest is far better than a having polished prototype with no customers. Christopher R. Chapman, president and owner of Derailleur Consulting, Inc., wrote:

“By the time you’re seeing VCs or angel funders you should be able to speak in terms of how many people are using your product and what your real expectations of a customer base are based on real-world feedback… To this end, get a minimum viable product in front of customers and run through the build-measure-learn-feedback loop. Accelerate the application of your learnings into your product, get some passionate early adopters and build a community of support that you can then take to investors as validation of the ideas. Of course, you could also learn from this exercise that your product isn’t that interesting to customers. Better to learn that cheaply rather than sinking a lot of money, blood, sweat & tears into a polished/pretty prototype.”

In short: Having a functional, if unpolished, prototype during a pitch meeting with an established audience means more to the investor than having a fancy-looking product nobody wants to buy.

Still, having a good prototype could make or break the pitch meeting. One thing all successful Shark Tank pitches have in common? A working prototype with a built-in fanbase. Conversely, a contributing factor to many flopped pitches on the program was a lack of interest in the product, accompanied by no more than a few rough sketches and hypothetical musings.

Some, however, argue that having a prototype too early might hurt your chances. Make sure you take the whole pitch process into account. Do some research about the companies where you will be presenting your invention. Find out what the next step for your product would be after pitching, and adjust your plans regarding prototypes accordingly.

Also, remember what a prototype is not: it is not a fully-functional version of the final product. It is not the product but missing a few key features or functions. It is a model of the invention, scaled down to be easily made with limited resources. If you’re pitching a bridge design, for example, you bring in a toothpick model as a visual, not a bunch of bricks. Vijay Anand, founder and CEO of the Startup Centre, explained that “the biggest mistake that most folks do, is trying to build a product when they keep saying it’s a ‘prototype.’ The other common mistake often made is that they take a product which has 10 features and essentially pick one or in some cases two, and then say, let’s build that and call that a prototype. Both of these are fundamentally wrong. A prototype is a much [more] basic version of the concept, not feature, to showcase what you are trying to do (aka, the solution).”

Creating a prototype is important to finalizing your product and turning your idea for an invention a reality. But it’s also not the final step. It’s another form of testing the waters, as well as gaining interest from consumers and investors alike. Prototyping is an industry of its own, one that continues to grow more prominent with each advancement. The rapid prototype model has helped many get their inventions of the ground. Hopefully, it’ll do the same for yours.